Belt Conveyors

The incredible winter concept

Half-way through the decade of the 90s the first lift using a belt conveyor was launched in Europe, nowadays, there are very few stations that don’t opt to use this equipment on debutant zones.

Tusa has found support in its expansive experience as a first brand in the sector of belt conveyors in order to create a line of belt conveyors that has revolutionized the market. TUSA’s lifts can have a width of up to 1200 which allows two users to ride simultaneously.

The entire design has been made in accordance with Regulation UNE: EN 15700:2012 for the safety of belt conveyors for winter sports and recreational activities and in accordance with ServiceTechnique of RemontéesMécaniques and TransportsGuidés(STRMTG): Guide technique du STRMTG – Tapis roulants des stations de montagne – Version 2 du 13 juillet 2017.

Talk to our specialists now!

Resources

Technical characteristics:

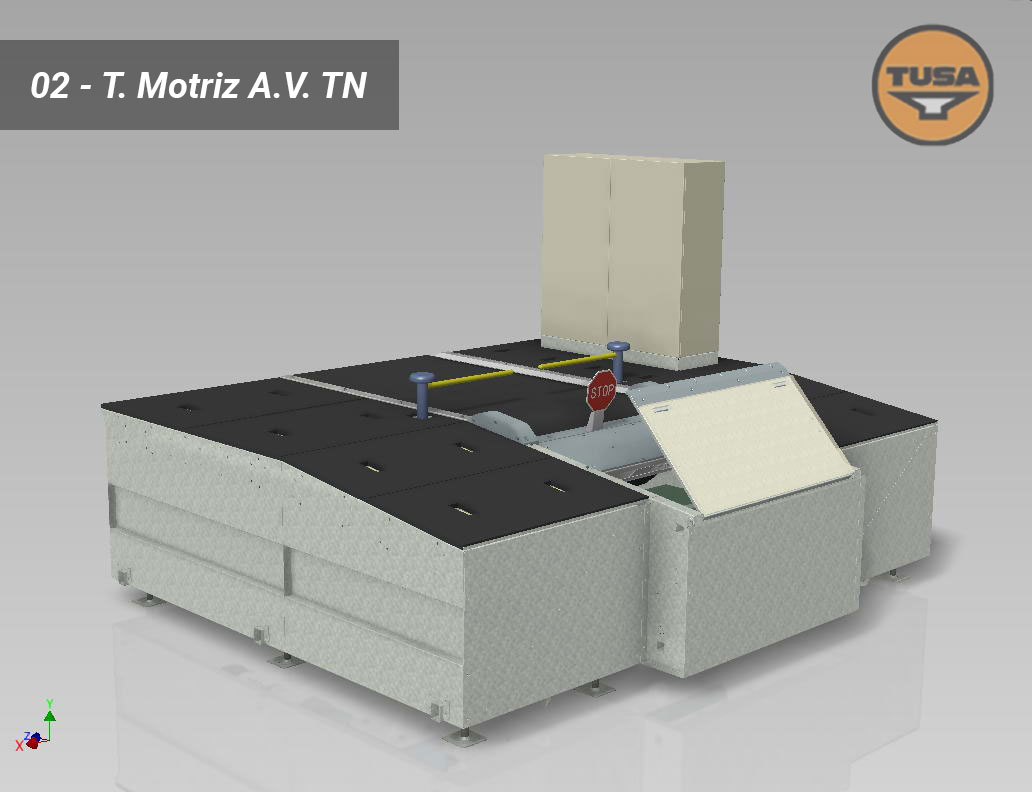

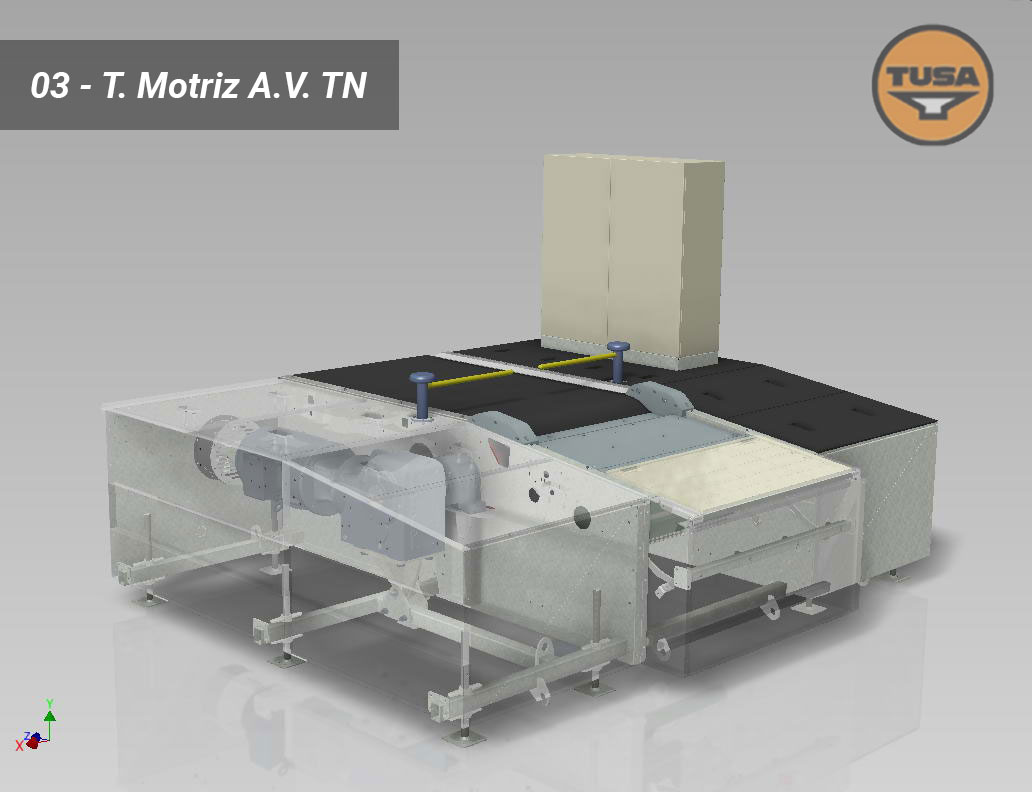

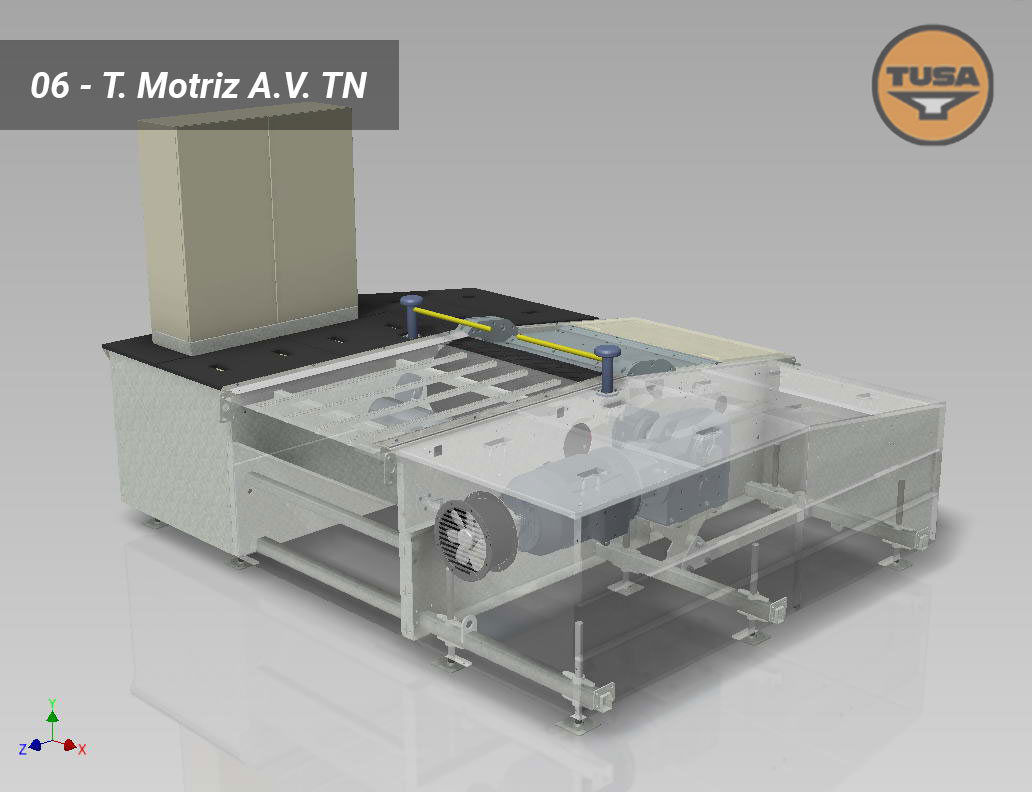

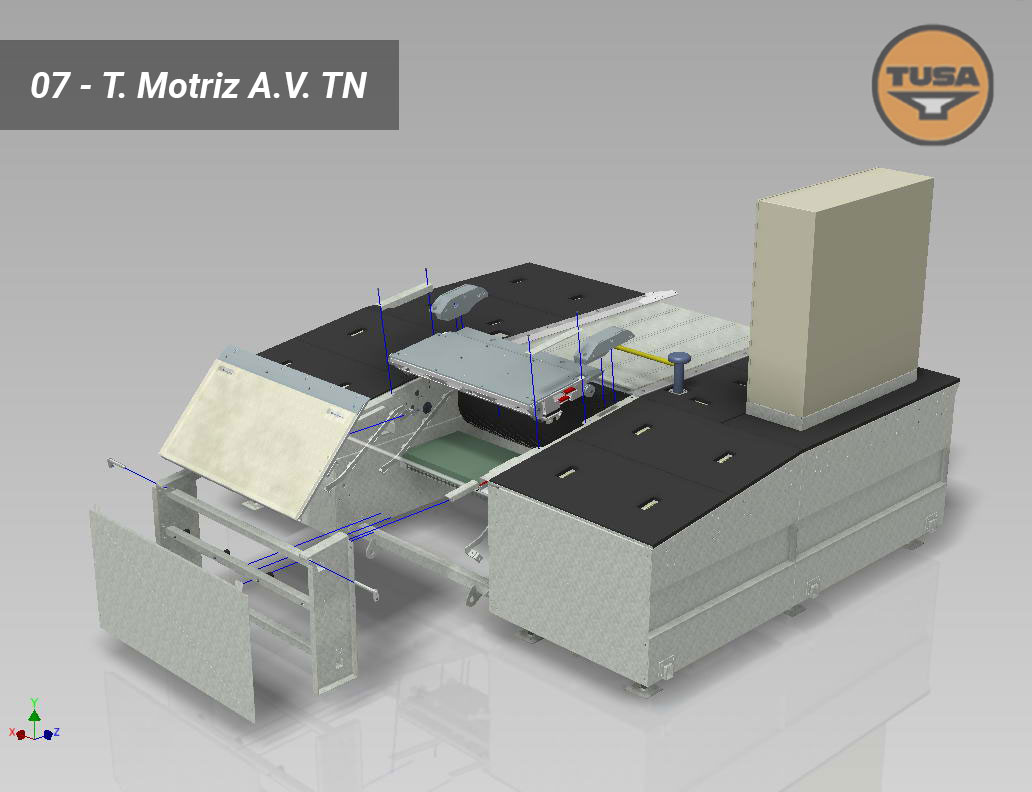

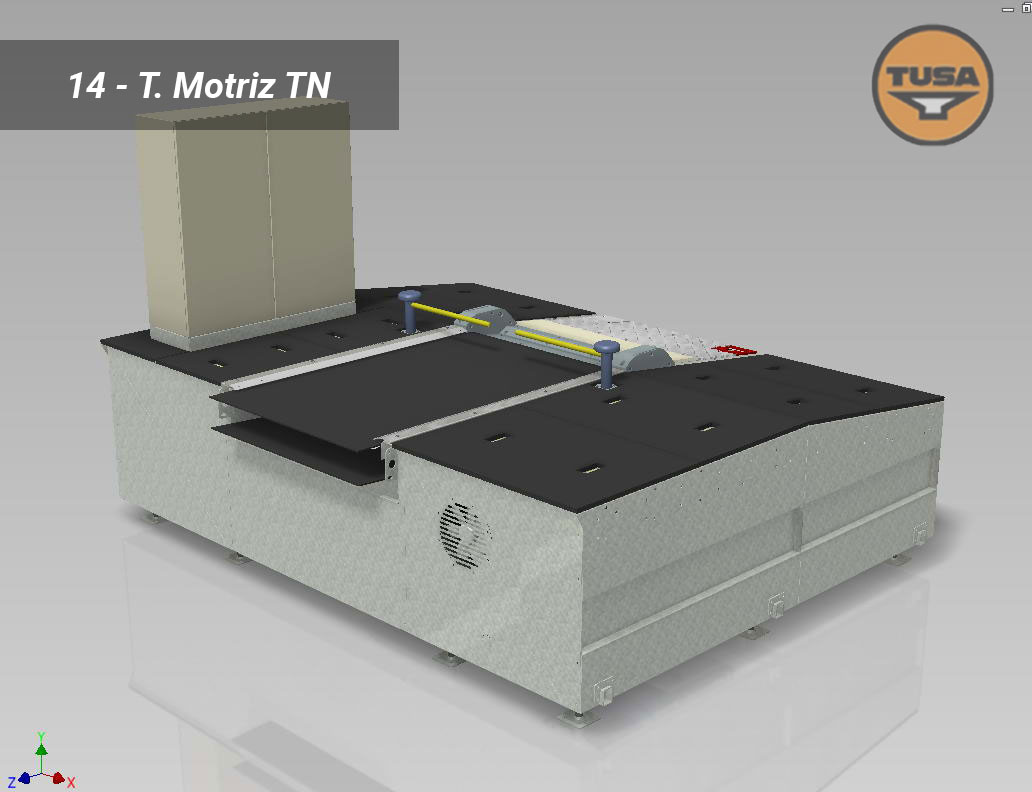

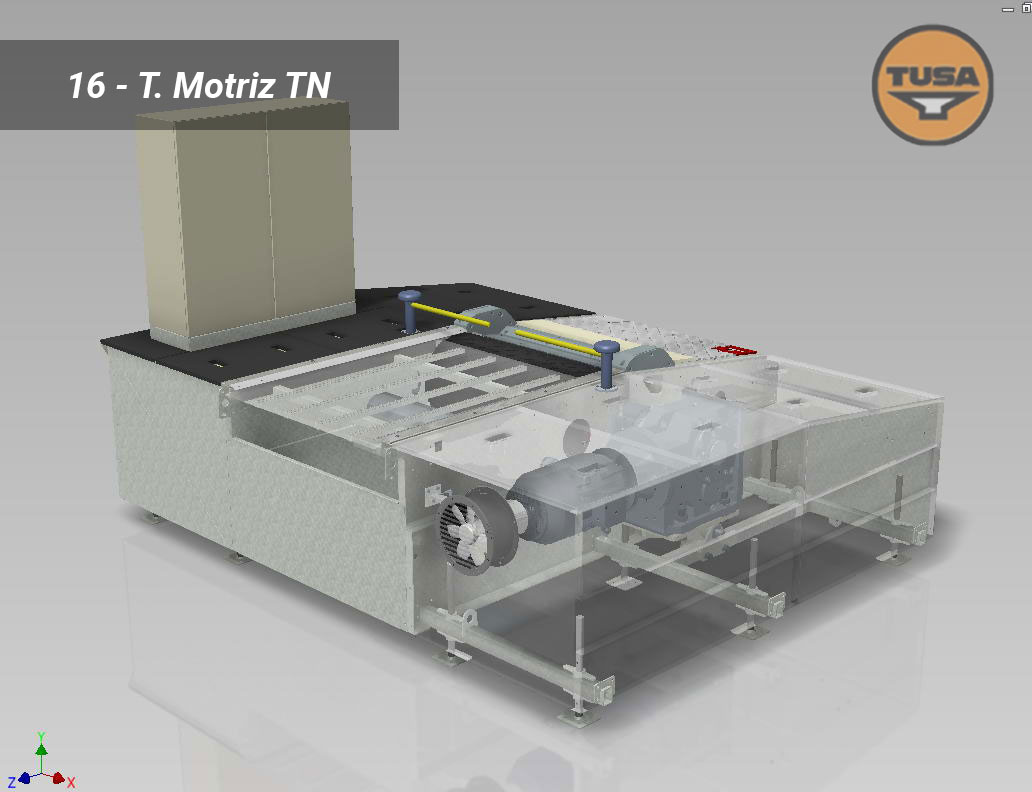

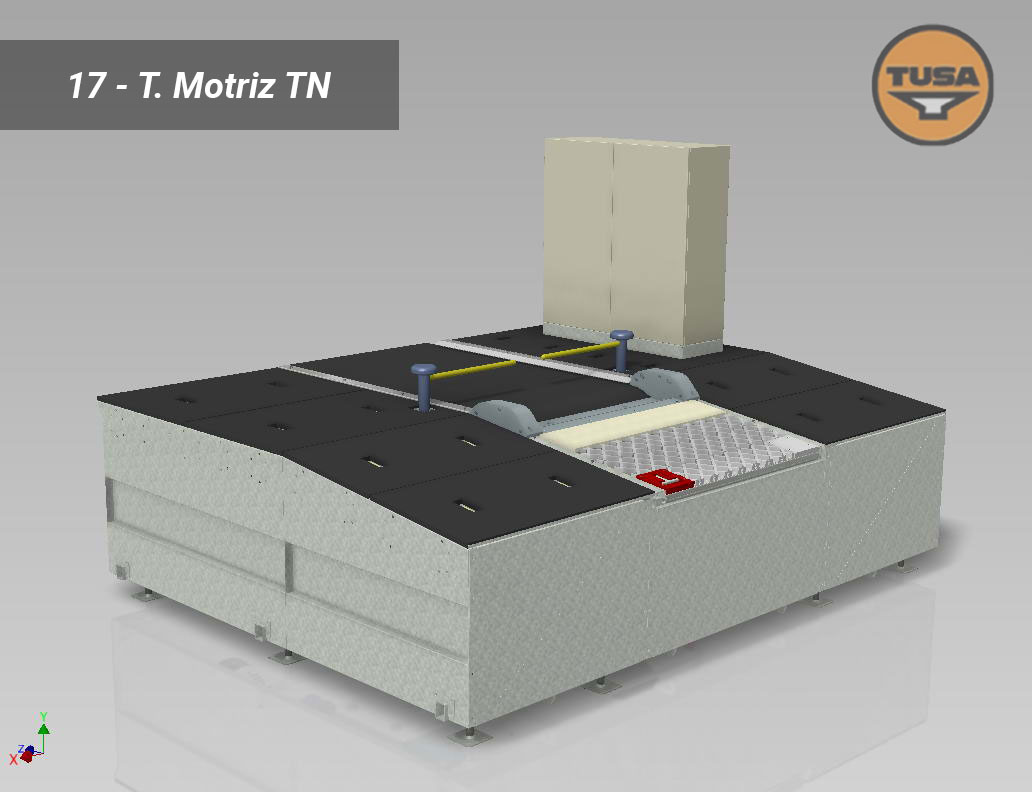

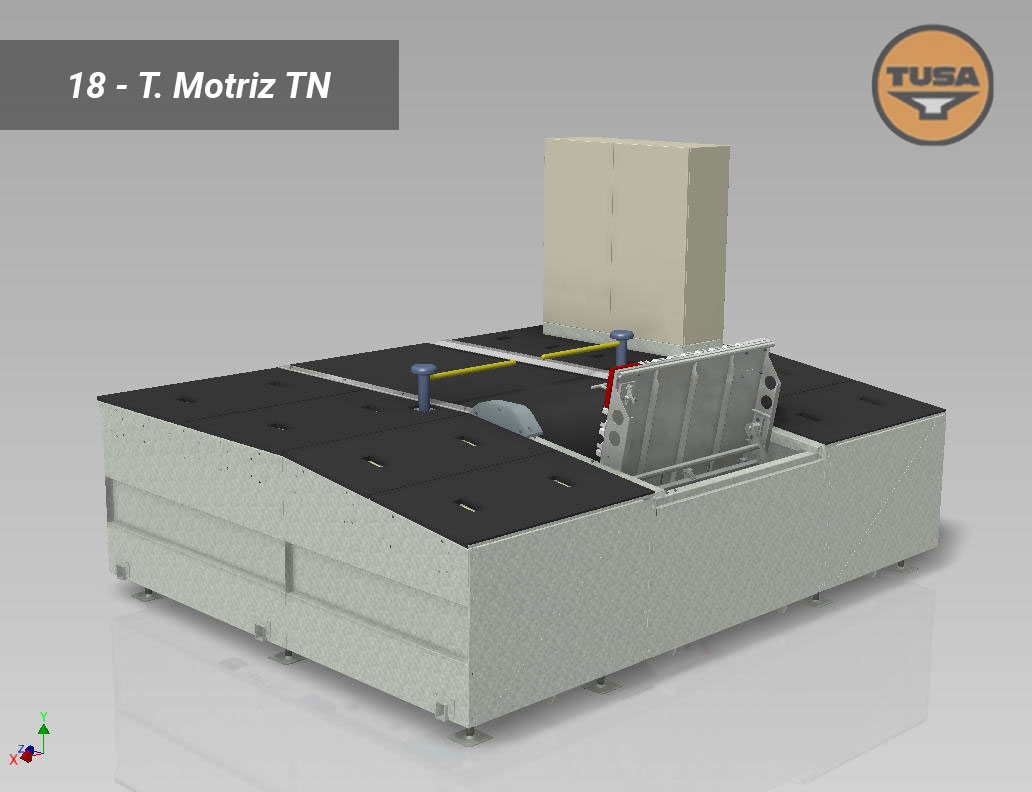

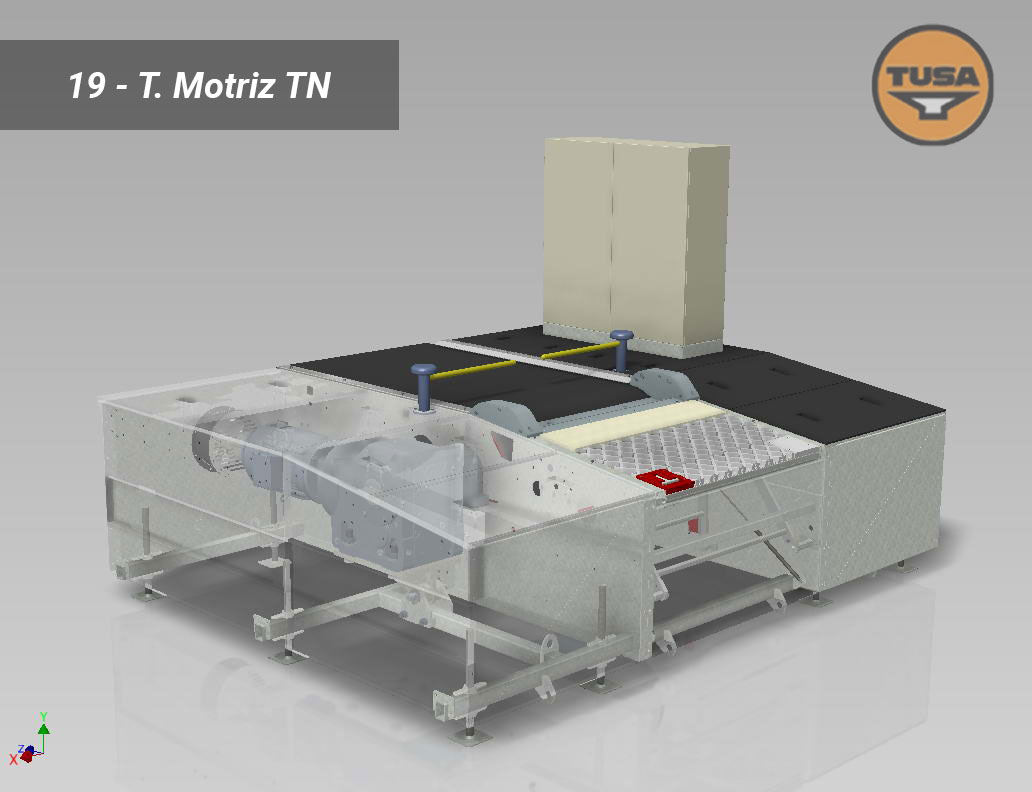

Motor Section

- Motor Section of belt conveyor designed in accordance with Regulation UNE:EN 15700:2012 for the Safety of Belt Conveyors for winter sports or recreational activities.

- Braking controlled by the regulator with programmable braking ramps that are resistant to power dissipation.

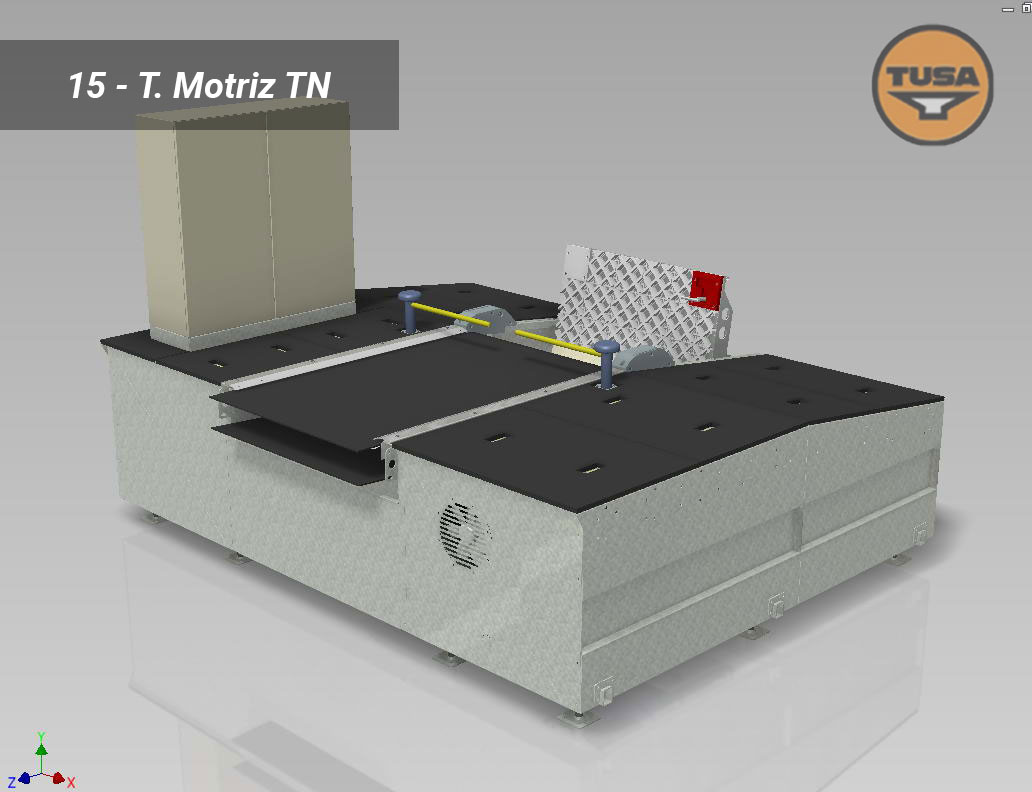

- Security systems through a sliding trapdoor installed at the landing of the mat, at the landing of the belt, which detects any type of entrapment stopping the belt with an emergency stop.

- – Rescue trapdoor installed at the landing of the mat making it possible to quickly release a person trapped between the belt and the security trapdoor. Security barrier with a double photocell on the landing of the belt, in accordance with Regulation EN 15700, with “emitter-receptor” technology of great sensitivity and easy adjustment.

- The trapdoor is automatic in versions of V= 1,2 m/s.

- Control sensors with information about the state of the drive system.

- Reinforced structure of galvanized steel.

- Adjustable support legs for correct levelling.

- Cleaning brush with independent motorization.

- Practicable corridors on both sides.

- Wide landing platform which can be adapted to the profile of the field, therefore allowing easy access.

- Completely careened driving unit.

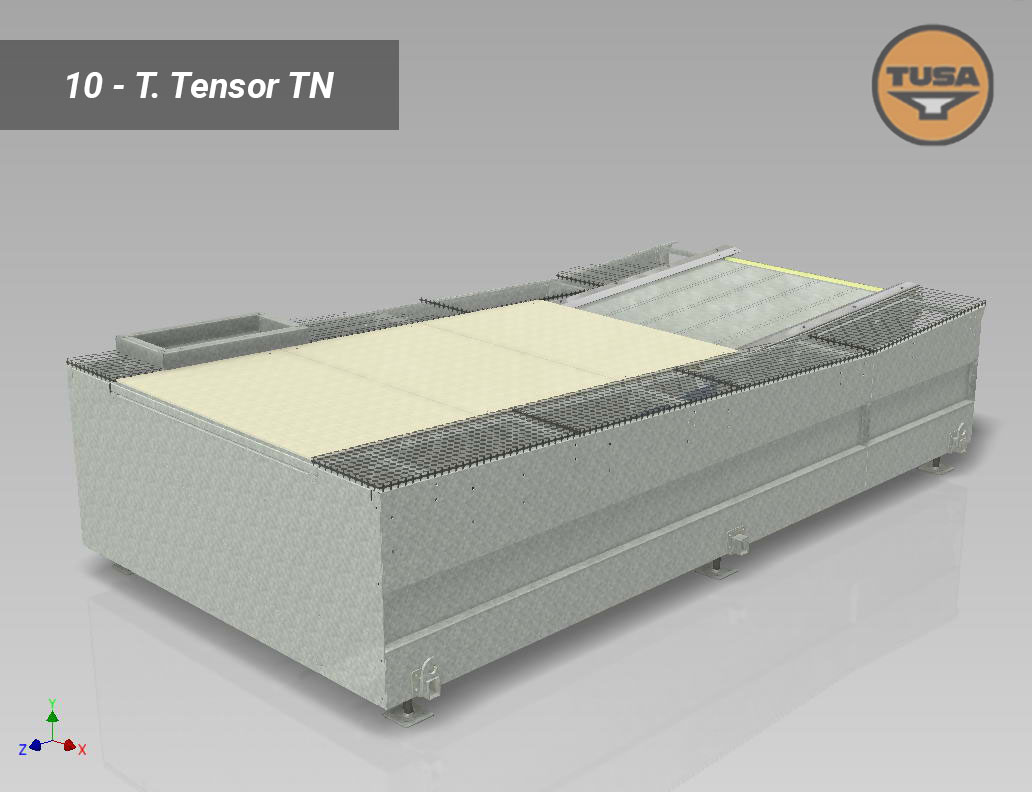

Tensor Section

- Tensor Section of snow belt designed in accordance with Regulation UNE:EN 15700:2012 for the security of Belt Conveyors for winter sports and recreational activities.

- Reinforced structure of galvanized steel.

- Adjustable support legs for correct levelling.

- Completely careened tensor group, without holes through which snow can seep in.

- Tension systems with spindles. Optional hydraulic system, manual or automatic.

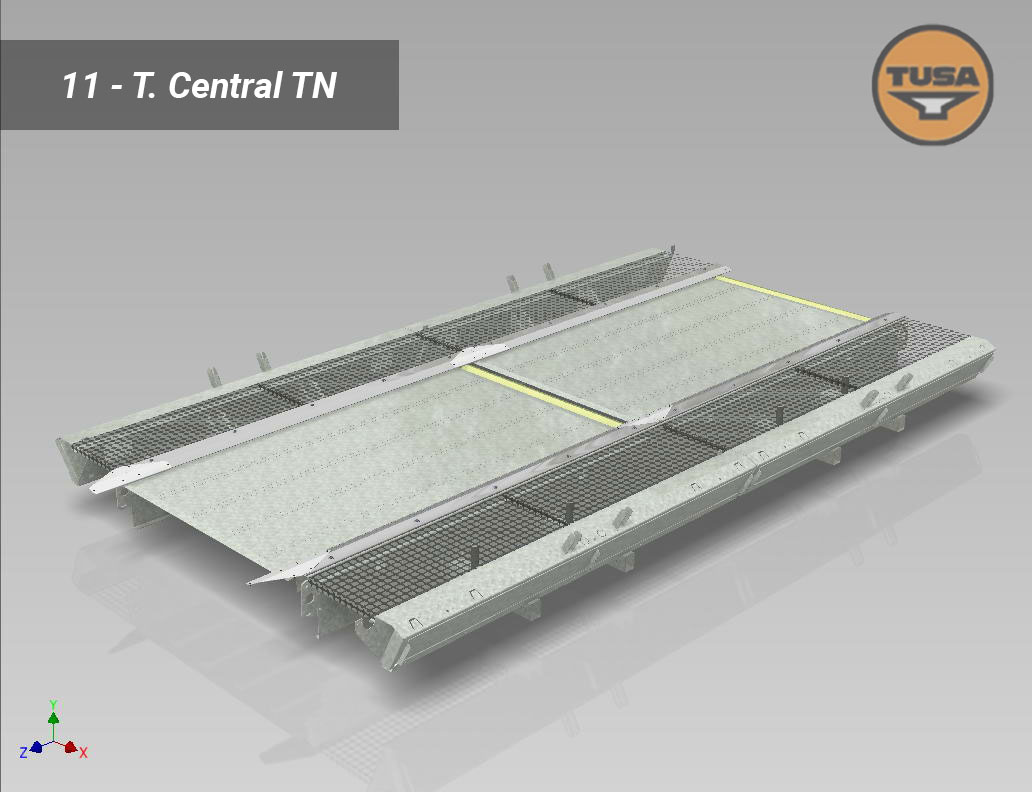

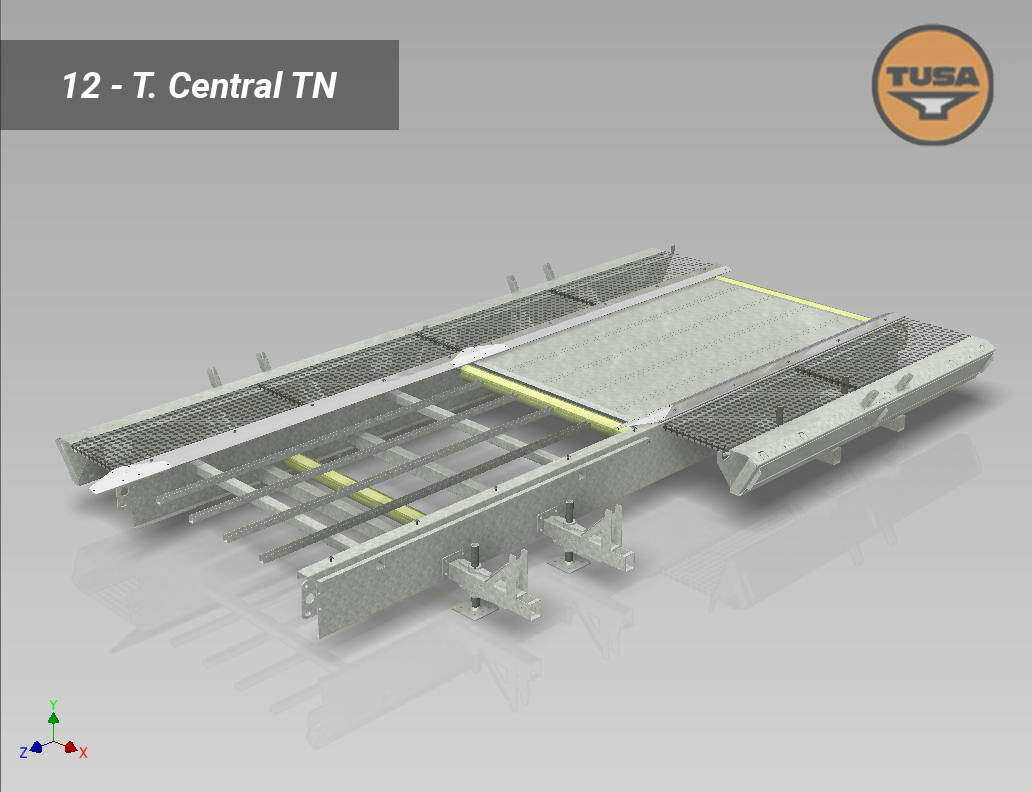

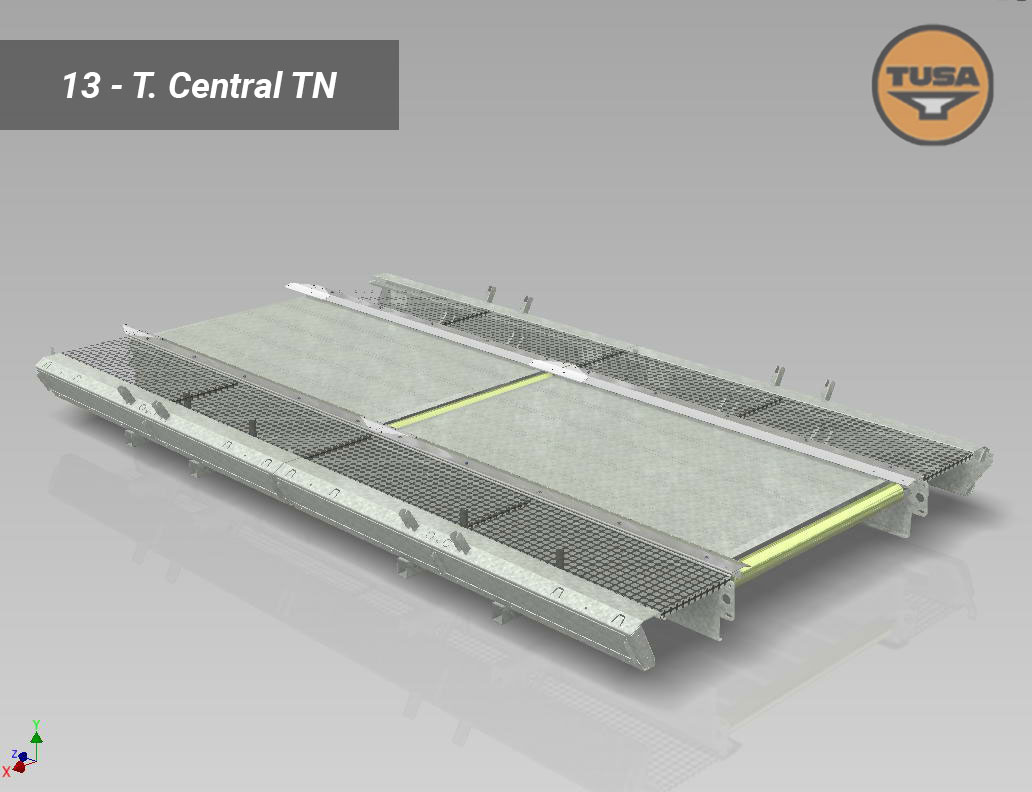

Central Section

- Reinforced structure of galvanized steel in standard sections of 4.2 meters.

- Cradle made of galvanized steel sheet with a low coefficient of friction.

- Inferior rollers of 89 mm in diameter every 2.1 meters for the return of the belt.

- Adjustable support legs for correct levelling and profile adaptation.

- Adjustable to the field through different connection angles between joint points.

- Guide profiles made in stainless steel with polyethylene profiles for attachment on joints.

Gallery

- Height 2.218mm.

- Lateral corridor with Tramex PVC floors, anti-skid, with capacity for up to 3 people by linear meter, meaning 240 Kg/mm.

- Resistance to overload produced by wind, for a speed of up to 200 Km/h and resistance to snow overloads, 2mt. on the sides and 1m on the cover (fresh snow, density 150Kg).

- Modular design, joints made with screws and strips, with the capacity to absorb differences in convexity and concavity of the terrain profile.

- Galvanized steel supporting structure.

- Gallery in transparent polycarbonate, resistant to UV rays at a height of 3000m. Material guaranteed for 5 years. Minimum thickness 5mm.

- The gallery has entrance and exit doors on the extremes with reinforced hinges to withstand the winds and an anti-ice lock.

- Emergency doors installed every 25m. for the exit of customers in case of emergency.

Electric control cabinet.

- Control cabinet with heating resistor for protection at low temperatures and ventilations.

- Programmable security controller of T3 class.

- PLC controller.

- Constant torque speed regulator.

- Alarm siren and boot notice.

- Velocity selector on the superior panel.

- Colour touch screen of 3.5’’ for management of the equipment, supervision of parameters of functioning and alarms

- Possibility of remote cabinet, communicated with the main cabinet through optical fibre.

- Possibility to visualize parameters via Ethernet.

- Remote technical assistance via Ethernet.